In the world of modern industries, the demand for efficient and reliable material handling systems has led to the rapid evolution of conveyor technologies. Hairise’s plastic conveyor belt solutions stand out as one of the most advanced and versatile options available. Offering a blend of durability, flexibility, and efficiency, these plastic conveyor belts cater to a wide range of industrial applications. Whether you’re in food processing, automotive manufacturing, or logistics, Hairise’s plastic conveyor belts are engineered to enhance operational productivity. With the ever-growing needs of industries, plastic conveyor belts from Hairise ensure smooth transport of goods, reduce downtime, and improve overall operational efficiency. The incorporation of plastic conveyor belts into modern industries has revolutionized production lines, and Hairise has consistently delivered top-quality solutions. The high-performance plastic conveyor belt systems from Hairise are designed to meet the rigorous demands of diverse sectors, helping businesses achieve higher throughput. Thanks to their robust design, these plastic conveyor belts are a trusted solution for many businesses looking to enhance their material handling processes. If you’re searching for a reliable plastic conveyor belt provider that integrates advanced technology, Hairise delivers outstanding results.

Hairise’s Innovative Approach to Plastic Conveyor Belts

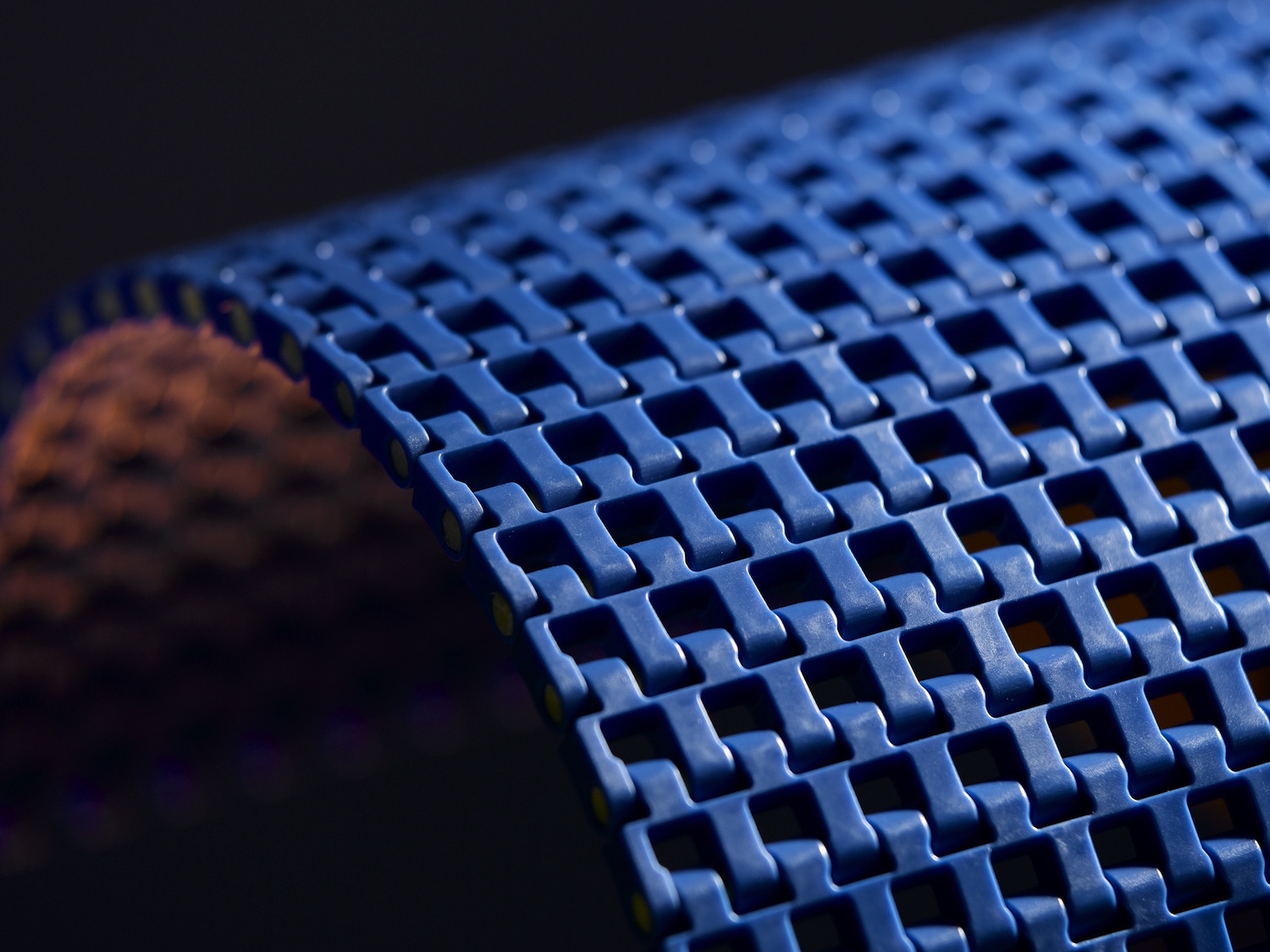

Hairise’s innovative approach to plastic conveyor belts has set them apart in the industry. By prioritizing quality, reliability, and cutting-edge design, Hairise has developed a range of plastic conveyor belts that meet the varied needs of industries across the globe. One of the key features that make Hairise’s plastic conveyor belts stand out is their modular design. These belts are easy to install and maintain, offering flexibility in adapting to different industrial setups. The plastic conveyor belt solutions from Hairise are specifically crafted to handle a wide variety of materials, from heavy-duty items in warehouses to fragile goods in food processing plants. With customizable options, Hairise ensures that businesses can choose the perfect plastic conveyor belt based on their unique requirements.

Moreover, the advanced materials used in the production of Hairise’s plastic conveyor belts provide excellent resistance to wear and tear, ensuring that the belts last longer and require less maintenance. This contributes to a reduction in downtime and maintenance costs, making the plastic conveyor belt system from Hairise a cost-effective solution for industries worldwide. Whether you’re looking for belts that can withstand extreme temperatures or need a system that supports hygienic transport in food processing, Hairise offers a versatile range of plastic conveyor belts to meet these demands.

Key Benefits of Hairise’s Plastic Conveyor Belt Solutions

The core benefits of Hairise’s plastic conveyor belt solutions lie in their durability, versatility, and operational efficiency. Firstly, the plastic conveyor belts are designed to be resistant to corrosion and abrasion. This makes them an ideal choice for industries such as chemicals, pharmaceuticals, and food processing, where exposure to harsh environments or heavy loads is common. Additionally, the material composition of Hairise’s plastic conveyor belts ensures that they are lightweight and highly resistant to oil, grease, and other contaminants, making them perfect for environments where hygiene is paramount.

The modular design of the plastic conveyor belts also allows for easy customization. Different belt configurations, sizes, and surface textures are available to suit various material handling tasks. Whether you need a plastic conveyor belt with specific incline angles, multiple levels, or sidewalls to prevent items from falling off, Hairise offers tailored solutions that align with your business needs. This level of flexibility ensures that industries can optimize their production lines, minimize space usage, and increase throughput.

Moreover, Hairise’s plastic conveyor belts are known for their smooth operation and low noise levels, which contribute to a more pleasant work environment. The smooth surfaces of the belts reduce friction, allowing items to move with minimal resistance. This results in more efficient material handling and contributes to a significant reduction in energy consumption, making these plastic conveyor belts an environmentally friendly option for modern industries.

The Versatility of Hairise Plastic Conveyor Belts Across Industries

Hairise’s plastic conveyor belts are designed to serve a broad range of industries, each with its own set of unique challenges. In the food and beverage industry, the need for hygienic, reliable, and efficient transport systems is crucial. Hairise’s plastic conveyor belts meet this demand by offering smooth, easy-to-clean surfaces that prevent contamination while ensuring consistent product flow. Their belts are certified for food safety and can be used in various stages of food processing, from washing and cutting to packaging and distribution.

In the automotive industry, Hairise’s plastic conveyor belts are used for heavy-duty material handling and assembly line applications. The robust construction of the belts ensures they can handle the weight of heavy parts while maintaining smooth operation throughout the production process. These belts also offer resistance to oils and chemicals commonly used in automotive manufacturing, making them a durable and low-maintenance option.

Logistics and warehousing operations also benefit greatly from Hairise’s plastic conveyor belts. With customizable configurations, these belts can be designed to accommodate a wide range of packages and products. Whether transporting small components or large pallets, Hairise’s plastic conveyor belts provide the flexibility needed to keep operations moving efficiently. Furthermore, their modular design allows for easy adjustments and expansions, ensuring that businesses can adapt to changing demands.

Hairise’s Plastic Conveyor Belts: The Future of Industrial Efficiency

As industries continue to evolve, the demand for more efficient and adaptable conveyor solutions will only grow. Hairise’s plastic conveyor belts are at the forefront of this evolution, offering industries a future-proof solution that combines advanced technology, sustainability, and operational efficiency. Their ability to integrate seamlessly with automation systems ensures that businesses can stay ahead of the curve in a highly competitive marketplace. Whether your goal is to reduce energy consumption, enhance operational speed, or minimize maintenance, Hairise’s plastic conveyor belts provide the perfect solution for modern industries.

Moreover, the ongoing research and development efforts by Hairise promise to further enhance the capabilities of their plastic conveyor belts. With an eye on the future, Hairise continues to innovate, ensuring that their products remain at the cutting edge of industrial conveyor technology.

In conclusion, Hairise’s plastic conveyor belts represent the future of material handling in a wide array of industries. With their durability, versatility, and high efficiency, these belts are poised to remain an essential component of modern industrial processes for years to come. By investing in Hairise’s plastic conveyor belts, industries can ensure a more streamlined, cost-effective, and sustainable operation.